The Think Circular 2025 forum held in Vilnius brought together experts in packaging, plastics, manufacturing, recycling, waste management and sustainability to discuss the European Union’s circular economy developments and their impact on business. The event highlighted not only technological and regulatory transformations, but also the growing importance of international partnerships. Special attention was given to cooperation with AIMPLAS, one of Europe’s most renowned plastics technology research organizations. Rosa González, a representative of AIMPLAS, analysed global trends in the plastics sector and outlined future directions for collaboration with the Lithuanian Plastics Cluster, which is a member of the organization.

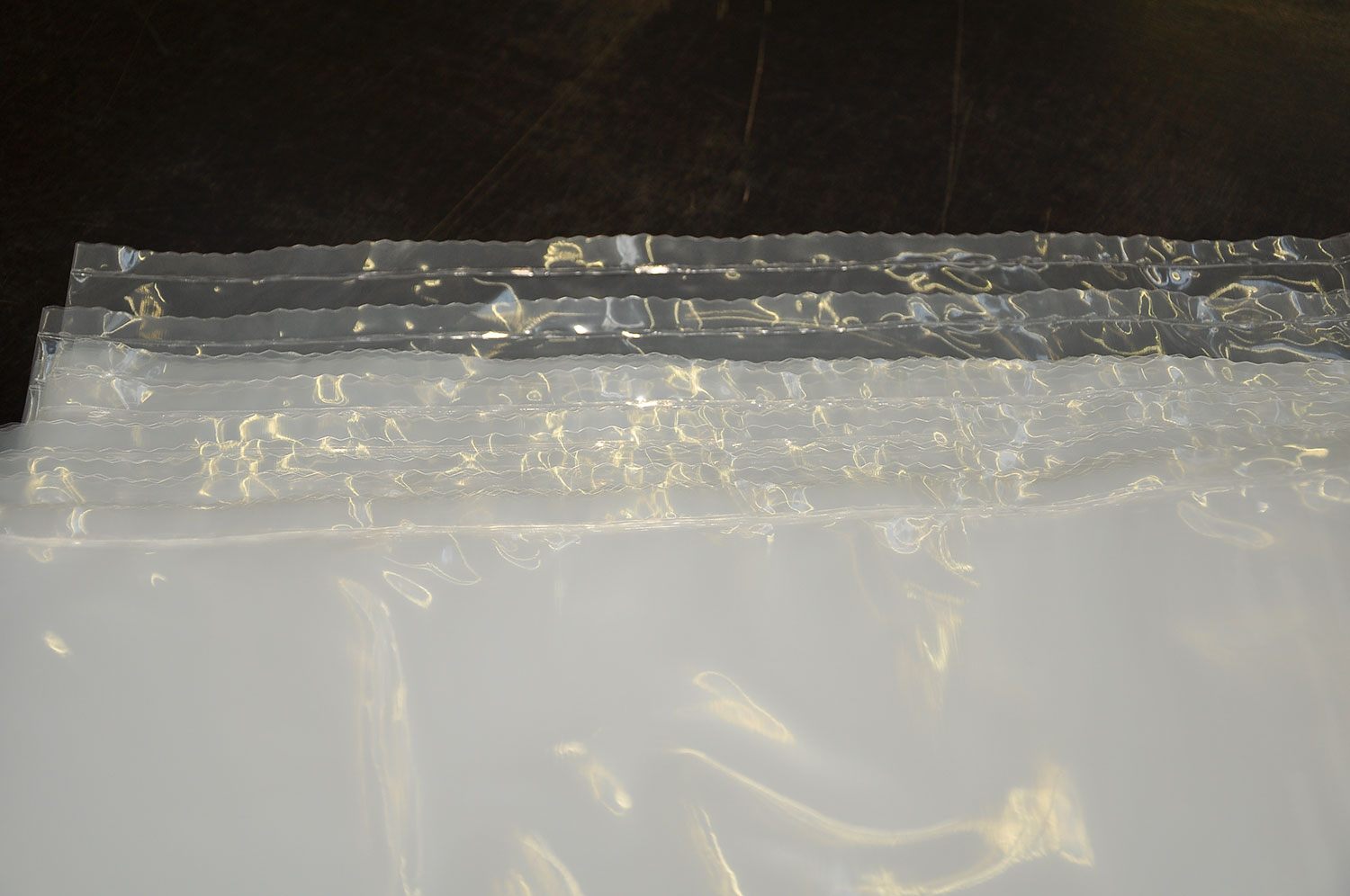

The forum thoroughly discussed upcoming EU legislation that will change requirements for the design, production and waste management of packaging and products. Regulation (EU) 2025/40, entering into force in January 2025, will introduce a new system for assessing packaging recyclability, obliging manufacturers to ensure recyclability aspects of packaging by 2030. The need to reduce excessive packaging elements, review material composition and increase the share of recycled raw materials was also emphasized. Another important step is Regulation (EU) 2024/1781, which introduces the digital product passport, ensuring more transparent dissemination of information on product composition, origin and environmental impact throughout its entire life cycle.

Ecodesign was presented as one of the key pillars of the circular economy, helping reduce material use and ensuring that products become easier to recycle or reuse. Speakers stressed the need to shift toward monomaterials, lighten packaging, and avoid design choices that hinder recyclability. The integration of renewable and recycled raw materials into production and the use of by-products in different industries were also highlighted.

Business sustainability transformation is impossible without cooperation. Companies within the Lithuanian Plastics Cluster actively share knowledge and jointly implement innovative projects, with one of their key goals being to strengthen their position in international markets. Cluster members aim to grow together by developing modern, sustainable solutions that can be competitive not only in the Baltic region, but also worldwide.

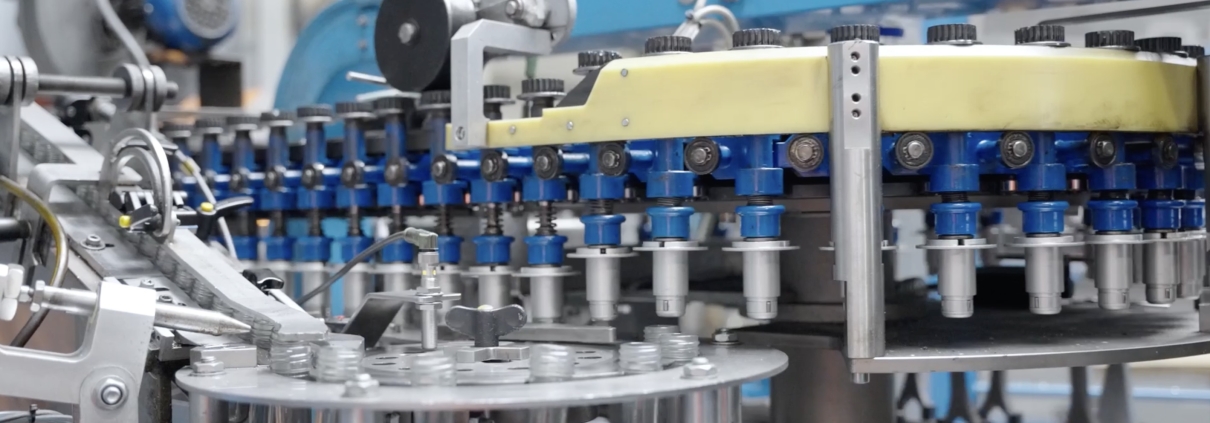

The event was enriched by numerous expert insights and practical examples. Sanna-Mari Kaakinen presented ABB’s experience in implementing “Zero Waste to Landfill” principles, Greta Česnaitytė reviewed the impact of the PPWR regulation on Lithuania’s packaging system, and Audrius Jasėnas discussed the financial and tax challenges that companies will face starting in 2026. FlexBlow CEO Gintautas Maksvytis also delivered an informative presentation, introducing advanced manufacturing and sustainability integration solutions. During the panel discussion, members of the Lithuanian Plastics Cluster – including Dovydas Stulpinas (Doloop), Marius Maslauskas (UAB Plastara) and others – shared their insights.

The networking session following the presentations provided participants with opportunities to build new partnerships, exchange experiences and strengthen cooperation between business, academia and the technology sectors. Participants unanimously agreed that progress in the circular economy depends directly on the ability to share knowledge and work together. The event organizers thank all participants and hope that these discussions will lay a strong foundation for future joint projects and a more sustainable future for the plastics and packaging sector.