https://plasticscluster.com/wp-content/uploads/2024/06/Pakavimo-linija-scaled.jpg

1279

2560

Jurgita Vajauskienė

https://plasticscluster.com/wp-content/uploads/2020/07/logo-1-300x111.png

Jurgita Vajauskienė2024-06-21 04:14:362024-06-21 04:22:24The Membership in Bydgoszcz Industrial Cluster

https://plasticscluster.com/wp-content/uploads/2024/06/Aim.jpg

1395

1882

Jurgita Vajauskienė

https://plasticscluster.com/wp-content/uploads/2020/07/logo-1-300x111.png

Jurgita Vajauskienė2024-06-11 05:56:112024-06-11 05:56:11The Lithuanian Plastics Cluster became a member of AIMPLAS

https://plasticscluster.com/wp-content/uploads/2024/04/1.jpeg

1266

1803

Jurgita Vajauskienė

https://plasticscluster.com/wp-content/uploads/2020/07/logo-1-300x111.png

Jurgita Vajauskienė2024-04-30 07:50:142024-04-30 07:50:14The Conference 'Recycling of Plastics'

https://plasticscluster.com/wp-content/uploads/2024/04/Screenshot-2024-04-30-at-12.40.08-e1714470714360.png

872

1994

Jurgita Vajauskienė

https://plasticscluster.com/wp-content/uploads/2020/07/logo-1-300x111.png

Jurgita Vajauskienė2024-04-25 07:33:272024-06-04 07:31:44The Letter of Intent with BICTV

https://plasticscluster.com/wp-content/uploads/2023/10/Interpack-1-scaled.jpg

1920

2560

Platicas

https://plasticscluster.com/wp-content/uploads/2020/07/logo-1-300x111.png

Platicas2023-05-16 06:36:042024-05-03 11:11:31The Business Mission and "Interpack 2023"

https://plasticscluster.com/wp-content/uploads/2022/03/klaster-linkedin-situation-08-web.jpg

788

985

Platicas

https://plasticscluster.com/wp-content/uploads/2020/07/logo-1-300x111.png

Platicas2022-03-23 06:34:052024-05-03 11:13:37Cluster members looking for solutions

https://plasticscluster.com/wp-content/uploads/2022/02/President_Doloop-1.jpg

840

2048

Platicas

https://plasticscluster.com/wp-content/uploads/2020/07/logo-1-300x111.png

Platicas2022-02-01 11:29:462022-02-01 11:38:47President's visit at Doloop

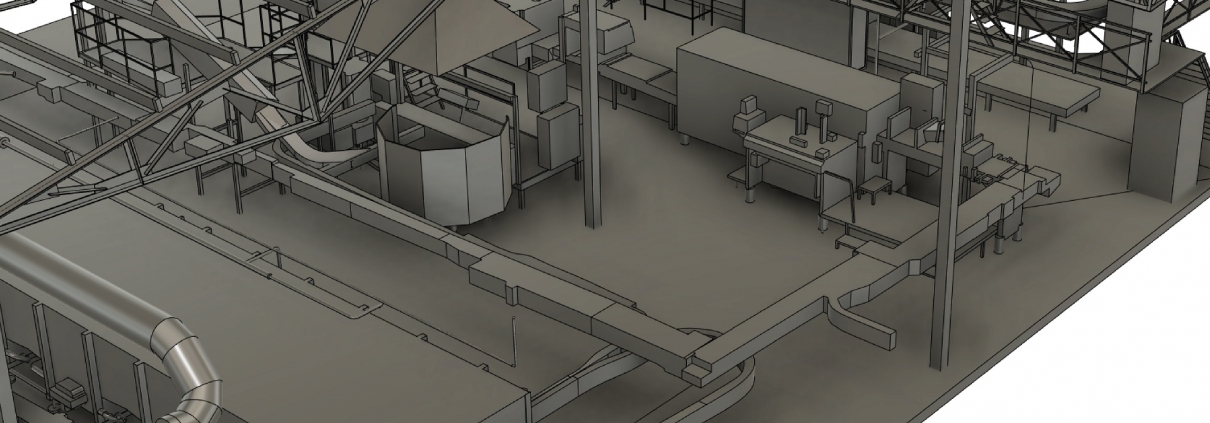

https://plasticscluster.com/wp-content/uploads/2022/01/3D_Creative_web.jpg

1576

1969

Platicas

https://plasticscluster.com/wp-content/uploads/2020/07/logo-1-300x111.png

Platicas2022-01-18 11:46:452022-01-18 13:43:113D scanning for accurate measurements

https://plasticscluster.com/wp-content/uploads/2022/01/klaster-linkedin-ktu-08-08_web.jpg

1576

1969

Platicas

https://plasticscluster.com/wp-content/uploads/2020/07/logo-1-300x111.png

Platicas2022-01-10 13:13:082024-05-03 11:09:34The Repulpability Laboratory at KTU

https://plasticscluster.com/wp-content/uploads/2021/12/Plastics_cluster_year_2021_web.jpg

1576

1969

Platicas

https://plasticscluster.com/wp-content/uploads/2020/07/logo-1-300x111.png

Platicas2021-12-30 05:00:512024-05-03 11:14:48A year marked by challenges and opportunities